2167 kh/h Hydrogen plant SMR method

Stock #AG66016

Used steam methane reforming (SMR) plant, designed to convert natural gas into hydrogen and carbon monoxide using a catalyst and steam. Designed capacity of 1800 Nm3/h of Hydrogen and about 2100 kg/h of a superheated steam. This plant was designed for a flexible and fully automated operation. All main equipment was made in Germany in 2012. Main components of the plant are Absorbers, Gas compressors, Desulfurizer, Boilers, Blowers, Tanks, Cooler, Separator, etc.

More information on request.

Location: East Europe

Add to Cart

View Details

743 TPD Air Separation Plant

Stock #ZG63613

Used Air Separation Plant

Rated 743 TPD nominal capacity

Product Purity: 95%-99.5% GOX

Product Delivery Pressure: 600 PSIG

Dresser-Rand compressor, Glitsch wash tower & chiller tower, Carrier Refrigeration unit, Atlas-Copco expander, Air Liquide cold box structure & Sulzer oxygen compressor.

Refurbished 2007-2008.

Location: United States

Add to Cart

View Details

Air separation plant the capacity of O2 is 400 KSCFH and N2 is 200 KSCFH

Stock #ZW63634

Used air separation plant for the production of gaseous and liquid oxygen, gaseous and liquid nitrogen and liquid argon. Production capacity range is as follows:

400 KSCFH of gaseous oxygen at 200 psig,

100 KSCFH of gaseous oxygen at 3 psig,

100 KSCFH of liquid oxygen, 200 KSCFH of gaseous nitrogen at 400 psig,

69.2 KSCFH of liquid nitrogen and 23.9 KSCFH of liquid argon.

The main vaporizer is a film-type with two BAHX closed cores supplied by Sumitomo and is equipped with alumina/CaBaX air purification system. Heat for regeneration is provided by the natural-gas fired

heater. HP column has trays, LP column and the two argon columns have packing. Argon production is “cryo-argon” type.

The LP liquid products are stored in two 525,000 gallon LOX and LIN flat-bottomed storage tanks. LAR is stored in

11,000 gallon tank. The HP LOX and HP LIN are stored in a 6000 gallon tank and 13,000 gallon tank, respectively.

The backup system is hot water bath vaporizer with an estimated capacity of 1000 KSCFH and multiple coils ( GOX,

GAN, and tank pressurization coils). The two hot water boilers are natural gas fired.

Main equipment and components:

Dollinger type AI-128-V-1400-480 air inlet filter

Main Air Compressor BLAC 1 - Cooper Industries type 4MSGEP9A, 4 stage, Radial, Integrally geared, Motor by GE, 8000 HP, 1800 RPM. Aftercooler by Basco type 70/64216, 2-stage, Shell MAWP - 350 psig, Tube MAWP - 150 psig.

Main Air Compressor BLAC 2 - Cooper Industries type 4MSGEP9A, 4 stage, Radial, Integrally geared, Motor by GE, 8000 HP, 1800 RPM. Aftercooler by Basco type 70/64216, 2-stage, Shell MAWP - 350 psig, Tube MAWP - 150 psig.

Evaporative Cooler Augusta Fiberglass, 8.5' x 37' 2-slage.

Chilled Water Pump Goulds model 3196MTX

Pre Purifier Vessels by Dacro.

Pre Purifier Dust Filter by NAFCO type 43200-1136B/SPL

Regeneration Heater by Gastech

Primary Heat Exchanger by Sumitomo

Nitrogen Superheater by Sumitomo

O2 Boiler by Sumitomo

Expander by Praxair by CDB-304

Turbine Booster Shell and Tube Aftercooler by BASCO type BEP29156

Booster Air/Booster N2 Compressor by Ingersoll Rand model 3CHB1B2, Radial, Integrally geared, 1st - 2nd stages - BAC, 3rd stage - BNC.

Air Booster Shell and Tube Aftercooler by BASCO type BEP 16156.

N2 Booster Shell and Tube Aftercooler by BASCO type BEP 10150

Baseload Nitrogen Compressor by Ingersoll-Rand type 2ASB40M3, Aftercooler by BASCO, Motor by Siemens,

Downflow Main Condenser, Argon Condenser and Argon Recondenser are made by Sumitomo.

LO2 Storage Tank by PDM

O2 Liquid Backup System Pump (2) by Cryomach

High Pressure O2 tank model TM6000

Argon Bulk Tank model TL-13,000

O2 /N2 Liquid Backup System by Cryoequip type WCVB-26-19-5

LN2 Storage Tank by PDM type LR-60

High Pressure N2 Tank type TM13,000

Cooling Tower by GEA Thermal Dynamic type TDJOJO·2·Z027CF

Cooling Water Pump (2) by Goulds type 3410L

Drain Vaporizer by J.D. Cousins

Nitrogen Chill Tower by Augusta Fiberglass

300 KW Backup Generator by Caterpillar,

Location: US

Add to Cart

View Details

Air Separation Unit Components for capacity 200 Tons / Day

Stock #RG9985

Used air separation unit components made in 1997 for capacity of 200 tons/day. First installed in 1977 and shut down in 2013. Designed by Air Liquide to produce:

- 100 TPD LIN (Liquid Nitrogen); 50 TPD LOX (Liquid Oxygen); 50-60,000 SCFH GOX (Gaseous Oxygen); 2.5 TPD LAR (Liquid Argon).

Major equipment includes:

- Clark ISOPAC MAC made in 1978 but rebuilt in 2000. Specs are 11,300 cfm, 95 psia, 3000 HP.

- Rix 2D-200 O2 Compressor.

- Clark ISOPAC Recycle Compressor rebuilt in 2000.

- Lotepro ETB 190 MS Expander.

- Nash Size 1253 DEOXO Unit made in 2006.

- CDI Mole Sieve Skid made in 2000.

- Ingersoll Rand Centrac Nitrogen Compressor type 12C5M3, 450 HP.

- Chiller 2000 HP

- Control panel, switch gear, transformers, loose piping.

NB: Does not include cold box or cooling tower.

Location: N/A

Add to Cart

View Details

Argon Recovery Unit, 33 tons/day

Stock #L0784V

Used Argon recovery unit operated from 1999 to 2002.

the feed gas is the tail gas from hydrogen recovery unit in ammonia plant.

1. Capacity

-. Liquid Argon : 33mt/day (11,000mt/year)

-. Nitrogen : 17mt/day (5,500mt/year)

2. Licensor : Linde AG, Germany

3. Year of start-up : June 1999

4. Year of closure : February 2002

5. Required area : 18 × 12M

further details available upon request

Location: REPUBLIC OF KOREA

Add to Cart

View Details

Hydrogen Gas Generating Plant 90,000 SCFH

Stock #ZG63448

Used modular hydrogen gas generating glant produces 90,000 SCFH (2300Nm³/hr.) of gaseous hydrogen at 200 PSIG (13.7 bar) with a purity of 99.99%.

Engineered by Hydro-Chem

Built in 1980.

The design capacity is 90,000 SCFH with a purity of 99.99% pure hydrogen - was running on only 10 tubes 45,000 SCF (1,182Nm³/hr). The reformer can be fired on natural gas or propane - same burner. Waste heat boiler generating, 3,000 to 5,000 lbs./hr. Export steam at 250 PSIG (17.2 bar). PSA plant. All 4 PSA vessels were replaced in 1998 with Jamesbury valves kept up to date, Quench pot design. Plant completely intact except for small natural gas compressor. Has new tubes, new reformer, and shift converter catalyst. Five (5) spare tubes available. The plant has just recently shut down in mid- 2012, and proper shutdown procedures were followed - still under nitrogen blanket.

• The plant was in operation until mid-2012.

• Was shut down properly using guidelines developed by Richard Daniel – plant still under nitrogen.

• Waste heat boiler was drained and dried – has desiccant packs in it.

• Boiler water treatment system is part of this sale.

• The small natural gas compressor is gone since they were using their own high-pressure gas – all the rest of the plant is intact.

• The control system is AB series 5. All the instruments are intact and installed and come with the sale as does the plc program and ladder logic. The AB5 plc and I/O’s do not since they are a part of the ongoing operation.

• Plant running on 10 tubes for 45,000 SCFH. Other tubes removed and burners were changed out for reduced production because of end users reduced H2 requirements.

• Five spare tubes come with this sale.

• H2 plant is enclosed in a building and reformer/vent gas drum behind a wind wall – and in good shape. Building is not part of the sale price but can be negotiated.

• All Fisher and Jamesbury valves have been kept up to date and changed as necessary – all in excellent shape

• All 4 PSA units changed out in August 1998.

• Gas plants are modular skid construction.

• Burner fired propane once a year to test it as a standby backup fuel – the main fuel was natural gas.

Location: Midwest USA

Add to Cart

View Details

Hydrogen Gas Generating Plant, 22500 Nm3/hour, 99.99% Purity, 33 barg

Stock #RG9402

Used hydrogen gas plant with capacity of 22,500 Nm3/hour and 99.99% purity. Plant which is based on Foster Wheeler Terrace Wall technology was commissioned in 2007 and shut down in 2011.

More information including process description is available on request.

Location: Europe

Add to Cart

View Details

Hydrogen Gas Generating Plant, 4.8 MMSCFD / 5200 Nm3/Hour, Modular

Stock #ZG62351

Used skid mounted modular hydrogen gas generating plant built in 1990, commissioned in 1991 and shut down in 2011. Designed and fabricated by Howe Baker Engineering with output capacity 5200 Nm3/hour (4.8 MMSCFD) at 13.7 barg and 26 degrees Celsius.

- Possibility to turn down capacity to 40%.

- Natural gas feed at 21 bar (300 psig)

- Product purity 99.98+%, pressure 13.7 barg at 26 degrees Celsius.

- Export steam 900 kg/hour at 173 deegrees Celsius at 3.4 barg/

- Single cylindrical reformer design

- (40) catalyst tubes

- (4) bed PSA system

- Waste gas surge tank

- PSA valve skid

- Plant configuration Bottom Fired Up Flow

Location: USA

Add to Cart

View Details

Hydrogen Generating Plant (Steam Methane Reformer) 5.8 MMSCFD, Modular

Stock #RG8758

Used modular hydrogen generating plant (or steam methane reforming plant) with approximate capacity of 5.8 MMSCFD (6,500 NM3/hour), reportedly made in 1995 and shut down in 2009. Natural gas feed pressure 253 psi, product pressure 200 psi.

Process takes the following main steps:

- natural gas conditioning - pre-reforming process - reforming process - Co. conversion - hydrogen purification - heat recovering - heating system - releasing system.

Major equipment includes the following:

- desulphurisation equipment

- PRE-reformer

- reformer

- process steam system

- gas cooling

- process gas cleaning PSA

- process control system

- pipelines and eta/MSR equipment.

More details about process and equipment are available on request.

Location: Europe

Add to Cart

View Details

Hydrogen Generating Plant, 160 Nm3/hour, Modular

Stock #KG61199

Reportedly unused hydrogen generating modular plant rated 160 NM3/hr purity 99.99% and steam. Feed by natural gas. Manufactured by Hydro-Chem/Linde.

Still in containers.

Location: EUROPE

Add to Cart

View Details

Hydrogen Plant (Steam Methane Reformer), 1700 Nm3/Hr

Stock #RG8764

Used 1700 Nm3/hour hydrogen plant (steam methane reformer) commissioned in 1994 by KTI and shut down in 2005. Originally 1500 Nm3/hour but upgraded in 1997. Plant has been kept under N2 atmosphere since shutdown. Plant produces 99.99% purity hydrogen. Major equipment includes:

- Desulphuriser

- Steam reformer

- HT-shift reactor

- PSA unit (UOP)

- Steam boiler with capacity of 1600 kg/hour of export steam

- Degasifier

- Boiler feed pumps

Original KTI documentation available.

Location: Europe

Add to Cart

View Details

Hydrogen PSA Unit with Capacity 36,000 Nm3/hour

Stock #RG2031

Used pressure swing adsorption (PSA) hydrogen unit made in 2001 based on UOP technology. Capacity is 36,000 Nm3/hour (32MMSCFD).

- Unit has (6) adsorbers 22 barg (319 psig) at 100 degrees Celsius (212 degrees Farhenheit), 41.3m3 (1458 feet3), 3000mm (118") OD x 5100mm (16.7") T-T.

- Hydrogen pressure into the PSA 19 barg (275 psig).

- Hydrogen pressure at the outlet of PSA system 37 barg (537 psig).

- Hydrogen purity at outlet 99.5%.

Location: N/A

Add to Cart

View Details

Hydrogen PSA with Output Capacity of 0.9 MM SCFD 99.99% H2

Stock #ZG63675

Used 5 bed syngas hydrogen PSA and tail gas compression system designed to process 2.0 MM SCFD and produce approximately 0.9 MM SCFD of 99.99% H2. Plant was built using a modular truckable design.

Location: USA

Add to Cart

View Details

Multi-Purpose Plant For Waste Gas Incineration

Stock #RG6563

Used multi purpose plant for waste gas incineration. Last used for incineration of ammonia loaded waste gas.

Location: GERMANY

Add to Cart

View Details

PSA Oxygen Generator made by Oxymat in 2012

Stock #RG2117

Used Oxymat O500 PSA oxygen generator made in 2012. Containerised system that includes the following equipment:

- Almig 45 belt air compressor, cyclone separators, air receiver, Donaldson DCO 360 AB dryer, Donaldson ultrafilter, Oxymat 2-column O500 system, oxygen receiver, Oxymat control panel, Rix compressor, low oxygen gas detection system.

Location: United Kingdom

Add to Cart

View Details

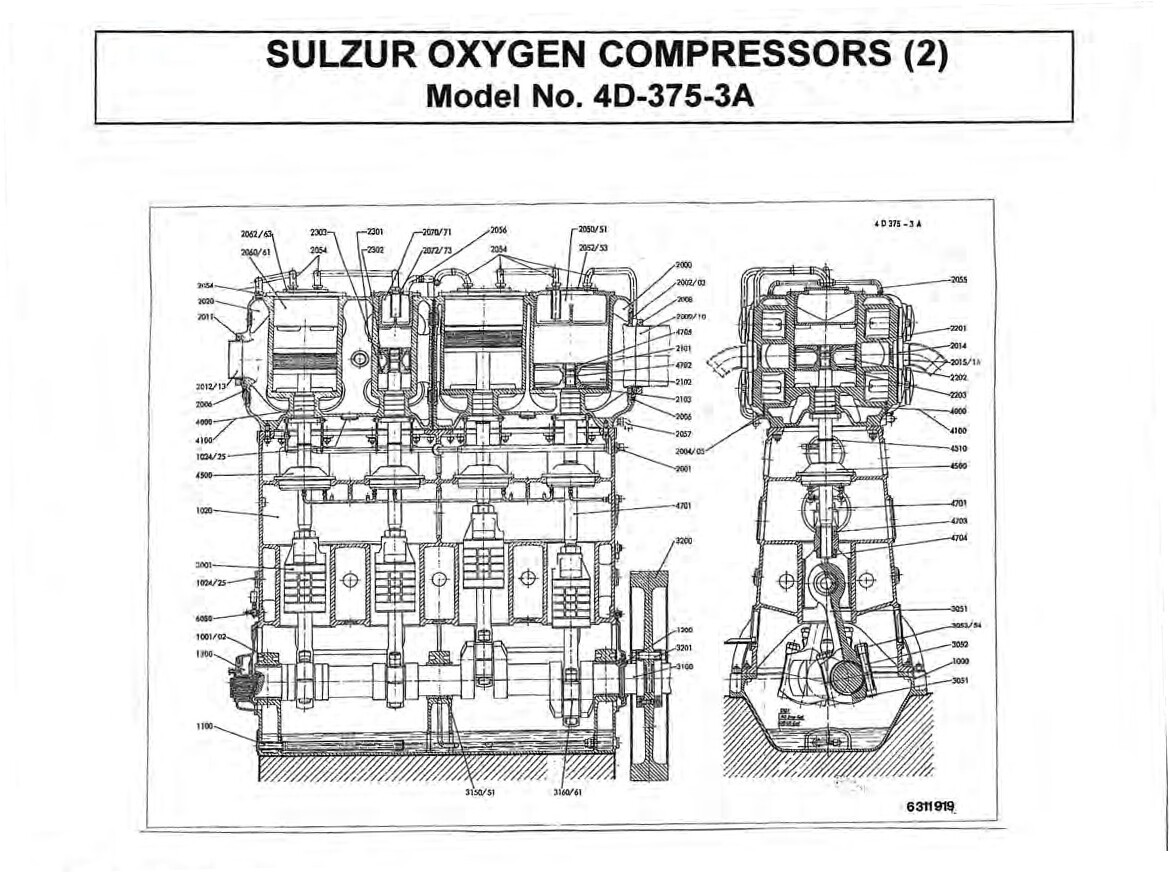

SULZUR Oxygen Compressor Model 4D-375-3A

Stock #ZW63627

(2) Rebuilt SULZUR oxygen compressors model 4D-375-3A. The flow rate for each compressor is about 743 TPD.

Suction pressure:

Stage1 = 1.21 bar, Stage2 = 3.4 bar, Stage3 = 11.52 bar.

Discharge pressure:

Stage1 = 3.55 bar, Stage2 = 11.93 bar, Stage3 = 40.76 bar

EQUIPMENT SUMMARY

- Compressors Dismantled, Inspected, and Refurbished by Burckhardt Compression

- All Refurbishment and New Part Replacement are detailed

- Interconnecting Piping, Volume Bottles and Coolers are included

- All Compressor Valves Refurbished

- Machine Parts packaged for Long Term Storage and Shipment

- Original Drive Motors refurbished by TECO-Westinghouse are included

- Foundation Design for Compressor and Drive Motor Included.

- Significant Spare Parts Inventory

More information available on request.

Location: US

Add to Cart

View Details

Used Hydrogen Plant with Capacity 25,000 SCFH

Stock #RG9805

Used hydrogen plant with capacity 708 Nm3/hour (25000 SCFH) of hydrogen with purity 99.99%. Made in 1977 by Hydro Chem and shut down in 2015.

Plant includes the following major equipment:

- Reformer designed with (8) tubes, (6) installed and (2) available.

- (4) PSA columns.

- Waste heat boiler provides approximately 1 ton/hour of steam at 16 barg (230 psig).

- High pressure gas compressor made by Gardner Denver with 45 kW (60 HP) drive.

- Siemens PLC & control panel, valves, pipes.

Utility requirements:

- Feed & Fuel Gas 1.74 MMBTU/Hour.

- Power 32KW.

- Steam 2100 lbs/hour.

- Water 425 gpm.

- Plot area 46 x 66 feet.

Location: Americas

Add to Cart

View Details

Air separation plant SUPAIRCO to produce Oxygen, Nitrogen and Argon.

Stock #ZW63522 Sold

Used air separation plant SUPAIRCO model MLONA-2500.

The plant can produce Oxygen, Nitrogen and Argon. The output capacity is as follows:

Liquid Oxygen, 99.5%, output (a) 25,000 SCFH, output (b) 15,800 SCFH.

Liquid Nitrogen, 99.999%, output (a) 17,000 SCFH, output (b) 30,100 SCFH.

Gaseous or Liquid Argon, 99,999%, output (a) 700 SCFH, output (b) 700 SCFH.

Gaseous Oxygen, 99.5%, output (a) 1,200 SCFH, output (b) 10,400 SCFH.

Gaseous Nitrogen, 99.999%, output (a) 55,600 SCFH, output (b) 42,500 SCFH.

Main components of the plant are as follows:

Inlet Air Filter self-cleaning.

Main Air Compressor Joy Turbo.

Air Chiller with ASME Separator.

Automated Mole Sieve by Superior Air Products. ASME coded vessels.

Recycle Compressor Joy Turbo.

Expander and Oil skid by Rotoflow GE.

Main Column has aluminum internals was built by Superior Air Products.

Liquefier Box has aluminum and stainless-steel internals was built by Superior Air Products.

Main Heat Exchangers are all aluminum plates.

Crude Argon column is made of aluminum and was built by Superior Air Products.

Argon Deoxo skid was build by Superior Air Products.

Liquefier Freon system Vilter.

The plant is complete with all control valves, controllers and analytical equipment.

More information on request.

Location: USA

View Details

Air Separation Plant, 150 Nm3/hr Oxygen and Nitrogen

Stock #RG8972 Sold

Used air separation plant with output capacity of 150 Nm3/hour oxygen and nitrogen. Reportedly installed in 2014 and currently operating at approximately full capacity. Purity of oxygen greater than 99.95% and purity of nitrogen greater than 99.999%. Manufactured by Oxyplant and Ingersoll Rand.

More details on request.

Location: Asia

View Details

Air Separation Unit, 43 tons/day

Stock #RG8990 Sold

Used air separation unit with approximate total capacity of 43 TPD. Supairco model MLONA-2500 oxygen, nitrogen and Argon plant built in 1980, shut down in 2014 and that has operated on stand-by for the last 10 years. Plant is mole seive type with production capacity options as follows:

- output option 1 (SCFH): 25000 liquid oxygen (99.5%), 17000 liquid nitrogen (99.999%), 700 gaseous or liquid Argon (99.999%), 1200 gaseous oxygen (99.5%), 55600 gaseous nitrogen (99.999%).

- output option 2 (SCFH): 15800 liquid oxygen (99.5%), 30100 liquid nitrogen (99.999%), 700 gaseous or liquid Argon (99.999%), 10400 gaseous oxygen (99.5%), 42500 gaseous nitrogen (99.999%).

Plant is dismantled, marked and ready for shipment.

Location: South America

View Details

Hydrogen Plant with Capacity 83000 SCFH

Stock #RG9807 Sold

Used hydrogen plant steam methane reformer type with capacity 83,000 SCFH of 99.99% purity hydrogen at 250 psig (17 barg). Built by Howe Baker in 1992 and currently idled but maintained.

Plant includes:

- (4) PSA pressure swing absorber columns.

- Waste gas steam generator boiler. Made by ABCO, exports 8000 lbs/hour steam at 185 psig.

- Reformer.

- Vent gas tank.

- Natural gas compressor.

- Gas train.

- Desulphuriser and shift converters.

- Heat exchangers, pumps, instruments.

- Spare Parts: set of psa system valves for reconditioning, new downcomer and ring, incolloy, (13) reformer tubes - incolloy, ID fan, assorted smaller spares .

Plant's (3) main modules housed in building sized 40' by 45', with the PSA, reformer, waste heat boiler and vent gas drum located outside. Total area used is 90' by 45'.

Location: USA

View Details

Hydrogen PSA with Output Capacity of 0.9 MM SCFD 99.99% H2

Stock #RG2071 Sold

Used 5 bed syngas hydrogen PSA and tail gas compression system designed to process 2.0 MM SCFD and produce approximately 0.9 MM SCFD of 99.99% H2. Plant was built using a modular truckable design.

Location: USA

View Details

Hydrogen Purification Pressure Swing Adsorption Unit with Feed Capacity 260 NMCH - Unused

Stock #RG1042V Sold

Unused pressure swing adsorption hydrogen purification system made in 2022. Designed to process syngas feedstock at flowrate of 260 NMCH to produce 160 NMCH of hydrogen with a purity level of ≥99.97%. (Capacity may differ dependent on feed gas composition and process conditions.)

Location: United Kingdom

View Details

Nitrogen Compressing Plant, 180 Nm3/hour, Unused

Stock #KG61822 Sold

Reportedly unused nitrogen compressing plant made by Haug (Swiss) in 2008 with capacity of 180 NM3/hour of gaseous dry filtered nitrogen.

Equipment list includes:

- (2) skid mounted Haug model QTODX 140/75/45/30 LM-L EEX II 2G B T3 oil-free compressors rated 90 Nm3/hour each, driven by 30 kw/1450rpm motor,

suction pressire 1.5-2 Bar, discharge pressure 96/101 Bar, ambient and suction temperature -20 up to +35 degC,

- (3) inlet air cooling units,

- (1) outlet air couuling unit,

- (1) control panel for both compressors,

- (1) set of valves, gaskets & stainless steel gas pipeline.

Location: EUROPE

View Details

Nitrogen Plant with Capacity 5000 m3/hour

Stock #RG9895 Sold

Used BOC Edwards Spectra-N plant for production of 99.9999% nitrogen with capacity 5500 m3/hour of gaseous nitrogen and 750 litres/hour of liquid nitrogen.

Commissioned in 1994 and idled in June 2020. Designed for use at sea level and 21 degrees Celsius.

Plant is ASU type and uses molecular sieve technology.

- Plant includes: (1) Atlas- Copco HLH-8 Main Air Compressor (2500 HP, 4160V), Siemens DCS controls with WonderWare HMI, spare compressor / expander / brake, 20000 gallon nitrogen tank, distillation column, heat exchangers.

Location: USA

View Details

Oxygen Plant VSA Dual Train with Capacity (2) 2337 Nm3/hour

Stock #RG1057 Sold

Used dual train modular VSA (Vacuum Swing Absoprtion) oxygen plant for on-site liquid oxygen (LOX) production. Commissioned in 2008 and shut down 2020/21.

Plant has a total oxygen production of 2x 2337 Nm3/hour (or 2x 79.4 STPD) with purity 90% (min 80%, max 95%).

LP O2 blower discharge. Flow and pressure 135 kSCFH at 12 PSIG min.

MP O2 blower discharge. Flow and pressure 25 kSCFH at 23 psig min.

Power at full production 1752 kW 5% at 85F.

Major equipment includes:

- Vacuum and air blower skid that includes silencers, suction filter, blower coupling, air blower and motor, vacuum blower and motor;

- Valve and chase skid that includes adsorber vessels, silencer / filter, GOX buffer, vent silence instrument air and membrane;

- Skid that includes buffer tank, membrane air dryers, water coalescer, oxygen compressor including: suction strainer, O2 blower coupling, O2 blower and motor, aftercooler and motor, discharge silencer, O2 discharge snubber, vent silencer.

Location: USA

View Details

Oxygen VSA Plant, 210 tons/day

Stock #RG8903 Sold

Used VSA oxygen plant with capacity of 210 TPD O2 of 93% purity. Reportedly commissioned in 2000 and shut down in April 2016. Major equipment includes:

- (2) compressors / blowers, (2) motors, (1) booster, (3) adsorber vessels, (1) air blower aftercooler, controls and model 95 plus motor control system.

More details available on request.

Location: USA

View Details

Part of Carbon Dioxide Recovery Plant, 1650 kg/hour

Stock #KG61933 Sold

Used part of CO2 carbon dioxide recovery plant with capacity 1650 kgs/hour of food grade CO2. Includes dryer and purifier only. Also actiators and control devices included, but no main control panel. Made by Techno Project Industriale (Italy) for brewery in 2008 and shut down in 2019. Manual included. More details upon request.

Location: EUROPE

View Details

PSA Nitrogen Generator System

Stock #VL1546-09 Sold

Little used Atlas Copco containerised Nitrogen generating system. System will produce approximately 125.5cumt/hr at 99% N2. Main components include:

1 off Atlas Copco model GA30 VSD+ P variable speed drive air compressor.

1 off Atlas Copco model FD140 refrigerant dryer.

1 off Atlas Copco model NGP100+ PPM nitrogen generator.

2 off Atlas Copco (CSC Italy) approximately 1,500 litre mild steel hot dip galvanised vertical air receivers.

1 off Atlas Copco (CSC Italy) approximately 500 litre mild steel hot dip galvanised air receiver.

1 off Bauer model PE-VE air compressor.

1 off container rack containing (16) 50 litre gas bottles rated 300 bar

Various filters, pipe work, instrumentation and controls.

All equipment is installed inside a type SR-STDQ-40DD (W1) mild steel 40' standard shipping container. Includes lighting, access doors and air ventilation.

Location: UK

View Details

Used air separation unit with capacity 12 TPD of LOX and 15 TPD of LIN

Stock #AG66006 Sold

Used air separation unit with the capacity 12 tons a day of liquid oxygen and 15 tons a day of liquid nitrogen. The purity is 99.5% for liquid oxygen and 99.99% for liquid nitrogen. Column diameter is 32 ½ inch (825 mm), length 72 Feet (22000 mm). Equipped with two Turbo Compressors JOY COOPER, first is 300 HP, second is 700 HP. Turbine NIKKISO type TC SERIES. Refrigeration unit VILTER type RECIPROCANTE model L78K-446-42F, 40 HP. 6.6 tons, -55 °F (-48°C), REFRIGERANT- AZ-50. Average power consumption is 835 kw/h. More information is available on request.

Location: N/A

View Details